In Amsterdam I met a man who revealed the hidden currents of our lives: the huge flow of raw materials and products used, with effects as wonderful as it is harmful, by 7.700 million human beings.Our collective metabolism, we could say.It was an autumn, cold and clear morning, and I was sitting on a magnificent pile of old bricks in the Oosterpark, a palace of curved halls, splendid staircases and useless turrets.A century ago, when the Dutch still extracted coffee, oil and rubber from their Indonesia neighborhood, this building was erected to host a colonial research institute.Today it houses various organizations dedicated to improving the world.Marc de Wit works in one of them: it is called Circle Economy and is part of an active international movement that has proposed to reform what has been our way of doing things in the last two centuries.

Wit, 39 and titled in Chemistry, opened a brochure and deployed a diagram that called "an radiography of the global economy".Unlike natural ecosystems, which work in cycles - plants grow on the ground, animals eat plants, their feces reopen the soil - the industrial economy is largely linear.In the diagram, thick colored currents of the four types of raw material (minerals, men, fossil fuels and biomass) ran from left to right, splitting and braiding when transforming into products that met seven human needs.The sand became the concrete of buildings built on six continents.Metallic minerals were transformed into ships, cars and also in harvesters: in a single year we harvest 20.100 million tons of biomass just to feed us.Fossil fuels propelled those vehicles, gave us heat, became plastic, became all kinds of things.The total volume that had reached the markets in 2015 amounted to 92.800 million tons.

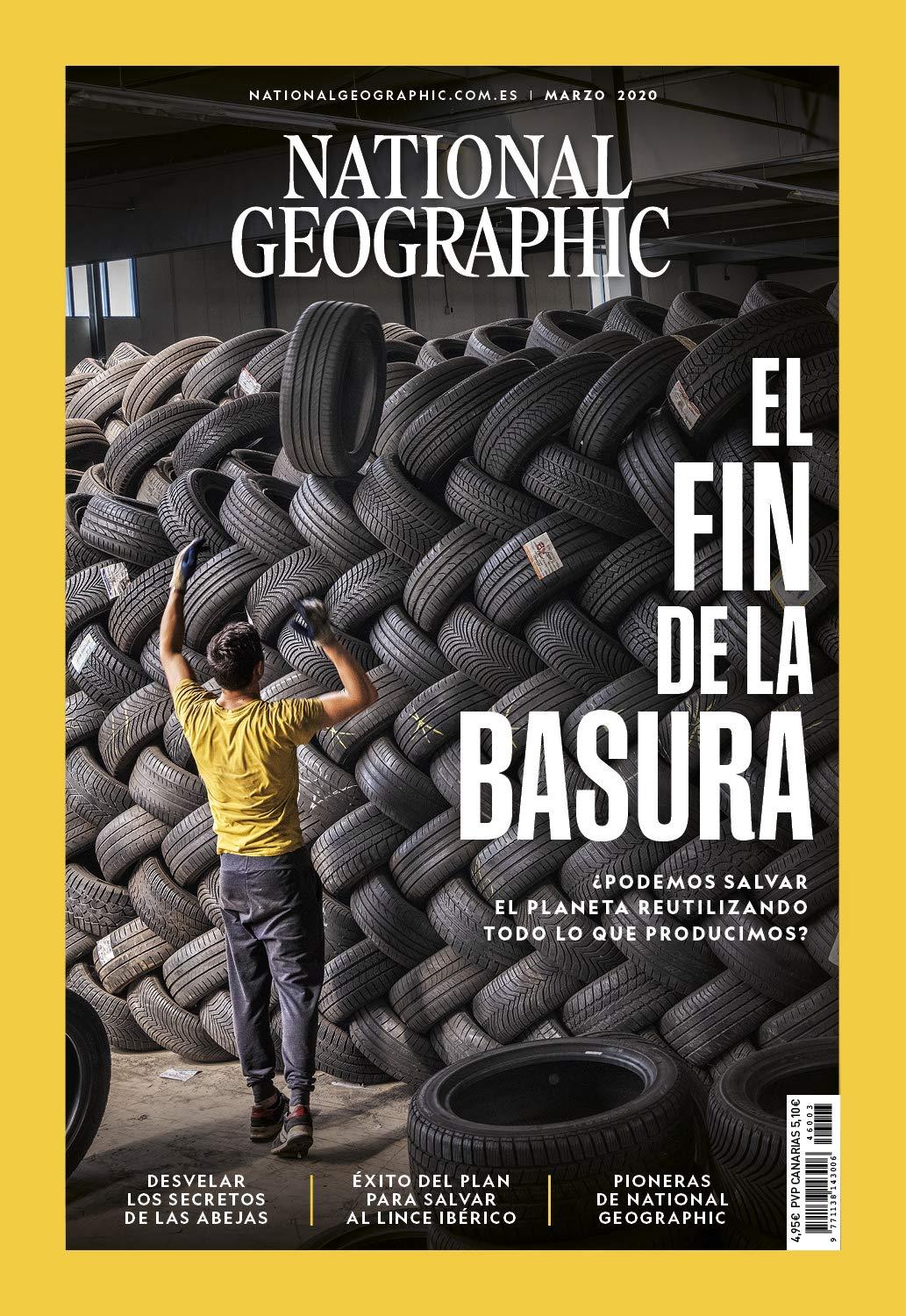

So far, everything correct;Even great, if you are one of those who admire before the ingenuity and work capacity of the human being.The problem comes later, from the moment our needs are met: in fact, there appears the head of all environmental problems.Wit pointed to the gray fog that occupied the right end of the diagam.That gray fog is garbage.

In 2015, he explained to me, about two thirds of the material that we started to the planet escaped us between the fingers of the hands.More than 61 were lost.000 million tons of resources obtained with effort, almost always dispersed in the environment without the possibility of recovering them.Plastic garbage went to rivers and oceans;The same happened with nitrates and phosphates dragged from the crops paid.A third of all food rotted, while deforested the Amazon to produce more.Think about an environmental problem: most likely it has to do with garbage.Climate change inclusive: if it exists, it is because we burn fossil fuels and throw the waste - carbon dioxide - to the atmosphere.

It will sound ridiculous, but that morning, while Wit explained to me the figures, I lived a revealing moment.There was a unifying and exciting clarity in that diagram, in his way of delineating the task.Yes, he said, we undoubtedly face varied and overwhelming threats.Okay that are dangers at planetary scale.But, let's see, to continue living on this earth, just do we do one thing: stop evil.From Wit a fine arrow that backed up in curve, from right to left, along the base of the diagram: it represented all the material we had managed to capture by means of recycling, composting and others.There were only 8.400 million tons: just 9% of the total.

That "circularity gap," as they called Wit and his colleagues when in 2018 they presented their report at the Davos World Economic Forum, it is relatively novel in the history of humanity.It arose when we began to give industrial use to fossil fuels in the 18th century.Until then, most human activities threw muscle strength, both animals and people.Cultivating, manufacturing and transporting things demanded large doses of work, which gave those things a great value.Our limited physical energy also restricted the impact we could exert on the planet.It is true that it also translated into a generalized pauperism.

Cheap fossil energy changed the panorama.Suddenly it was much easier.Fossil fuels fired our possibilities, and the process continues to intensify today.In the last 50 years, while the population of the world has doubled, the amount of material that moves in the economy has been tripled by far."Now we are reaching the limits," said De Wit.

During that same half century environmentalists have dedicated themselves to warning us about growth limits.The new movement in defense of the "circular economy" is different.It is based on a series of strategies - some solera, such as the philosophy of reducing, reusing, recycling;other innovative, such as renting instead of possessing - that together they intend to reform the global economy to eliminate garbage.The circular economy does not seek to end growth;wants to return our way of doing things to harmony with nature, precisely so that this growth can continue."Prosperity in a world of finite resources", as expressed by the European Commissioner of Environment, Janez Potoeik, in the prologue of a report from the Ellen MacArthur Foundation.The report claimed that the circular economy could save European companies up to 630.000 million euros a year.

The idea is caught, especially in Europe, a small continent, crowded with people and rich, but poor in resources.The European Union is investing billions of euros in this strategy.The Netherlands have pledged to reach total circularity before 2050.Amsterdam, Paris and London have their respective projects."There is no alternative," said Wayne Hubbard, head of the London Waste and Recycling Commission, when I asked if I thought the circular economy was feasible.

A person who believes her totally feasible, and whose work has opened the eyes of many, is the American architect William McDonough.Together with the German chemist Michael Braungart, he wrote the visionary book of 2002 Cradle to Cradlepremium of subsequent products and processes.Before leaving for Europe, I pilgated to Charlottesville, in Virginia, to see me with McDonough.The conversation jumped from his childhood in Tokyo to some new compostable jeans that had him excited, passing through Plato, Aristotle and Buckminster Fuller, until I finally managed to ask the pressing question: Is this discourse about the end of the garbage a toast to the sun?

"Totally.You may be very sure, ”said McDonough.".And less bad, because we need toast to the sun to continue moving forward.Remember what Leibniz said: "If possible, then it exists".And I say: "If we can make it exist, then it is possible" ".

Was it a tautology?Had Leibniz really said that?At least, he gave to think.Shortly after I led to my battered travel trolley (a very circular gesture compared to buying another), I put the jeans with Cradle to Cradle Certificate (C2C) that McDonough gave me and left, determined to find out what evidence of the existence of the economy of the economyCircular managed to find.

Metals

The first gaps of our natural circularity are actually prior to the industrial revolution of the 18th century.The Romans were pioneers of a hairy invention: the sewer.In other words, human excrement channeled to the rivers instead of returning them to the fields, which, as any circularity expert will be delighted, are their natural destiny.In the fifties, when I was little and lived in Tokyo, McDonough woke up at night with the noise of the peasants who collected the sewage of the family.

The Romans, as the Phoenicians did before, also extracted copper from the rich deposits of the Andalusian River.But at the same time they recycled: they founded the bronze statues of the towns that conquered to make weapons.Copper has always been very sought by recyclers.Compared to fecal waters, it is scarce and valuable.

In the patio of the Copper Aurubis de Lünen smelter, in the German Ruhr basin, a great bust of Lenin stands in a partter, memory of the countless bronze lenins molten in the plant.They began to arrive from all oriental communist Germany from the 1990 reunification.Aurubis, the first copper producer in Europe, is also the largest copper recycler in the world.When the Lünen plant was inaugurated in 1916, in the first World War."Since then this plant has been dedicated exclusively to recycling," says its deputy director, Detlev Laser.

Copper, unlike –mot for the case - the plastic can be recycled infinitely without its quality: it is a perfect circular material.The Lünen plant continues to process the weight, almost always pipes and cables, but it has had to adapt to waste that has much lower concentrations.As Europe has been replacing landfills with incinerators, a large amount of slag with metal fragments appears, "because someone threw their mobile" and did not take it to the green point, says Laser.

With Hendrik Roth, environmental director of the plant, I saw how an excavator dropped electronic waste (such as laptops) on an inclined conveyor belt that led them to a destructive: it was the first of the more than twelve steps that made up the disconcerting and deafeningclassification process.In a position, a conveyor belt ran at full speed loaded with electronic circuit fragments of the size of one hand.Some fell into an abyss;others jumped as of their own will to another superior tape.A cameras system, Roth explained to me, decided what fragment contained metal;If he did not detect it, he activated a jet of air at the exact moment to raise it.

Aurubis sells aluminum and plastic that recovers the respective industries;Copper and other non -ferrous metals end in their own furnaces.The Immaculate Patio sweeps every day;The collected dust goes straight to the ovens."Nothing is discarded here," says Laser.

In the world it is only recycled around a fifth of electronic waste, a UN report pointed in 2017.Aurubis even receives remittances from the United States."But sometimes I wonder why such an industrialized country happily renounces such valuable resources," says Roth. ".They have billions of dollars dead laughing ».

But copper exemplifies a general challenge: until the most energetic recycling has a limit.In Aurubis, recycled copper is only one third of production;The rest keeps from mines.In the last half century, world copper production has quadrupled, and continues to increase.The technologies we need to get rid of fossil fuels demand large amounts of copper;A large wind turbine uses about 30 tons.

"Demand grows," said Laser, ".It is impossible to satisfy it recycling ».The circular economy will require other strategies.

Clothing

The Ellen MacArthur Foundation logo, a group of nested circles, stood out in Dame Ellen's sweatshirt when I met her in her headquarters on Wight's island.In 2005, at 28, MacArthur circulated the solo balloon aboard a 23 -meter trim will in a record time of 71 days and a few hours.I wore food for 72 days.Had fought with temporary in Antarctica and fixed a spoiled generator.He came home with a visceral consciousness of how limited are the resources.

Why didn't we talk about that? He wondered.He left the competition candle and founded an organization that has done more than any other for promoting the circular economy, using a priority of strategies (see the following diagram).The best is the simplest: discard less things keeping them in use.

It is a advice that often crashes against people's wardrobe.Between 2000 and 2015, while the world population grew 20%, the production of clothing garments doubled, according to a report by the Ellen MacArthur Foundation, thanks to the explosion of "fast fashion".With so much cheap clothes, in 2015 we gave three times less use to garments.That same year the world threw more than 400.000 million euros in clothing.

Jorge Boer earns life by rescuing part of those garments at the head of the Boer Group, a Dutch family business that started a hundred years ago when his great -grandfather gathered through the streets of Rotterdam rags, metal and paper.Today, since its headquarters in Dordrecht, Boer manages five plants in the Netherlands, Belgium, France and Germany.In total they collect and classify - and they resell for reuse or recycling - up to 415 tons of discarded clothes a day.

People have a wrong idea of what happens when they leave clothes in a donation container, Boer told me;believe that the garments are delivered to the needy.But what usually happens is that a company like Boer buys donated clothing, classifies and reverts it throughout the world.

"There is a lot of experience to know where you can sell and reuse a garment," said Boer.Through the glass on his back, he saw the quick but archiensayados movements of the women who withdrew garments from the tapes, examined them quickly and turned to throw them to one of the approximately 60 classification bags.Each operator classifies almost three tons per day.They must have a good eye, especially to detect quality garments - there are 5 or 10% of the total - that report the bulk of Boer's benefits.In Russia and Eastern Europe, the most precious items - such as women's underwear - can be quoted at five euros per kilo.Most of the lower quality material refers to bales of 55 kilos to Afric.

At one point Boer scrutinized my gray American;I was calm: the ink spots of the inner pocket were not seen.«His American cannot sell it anywhere.There is no human being in the world willing to buy it, ”he said happily without anyone asking him.In fact, he added, I would have to pay for someone to take my outdated garment.

But used underwear are willing to buy it, right?I had touched the fiber a little.

"It's used but clean underwear," said Boer.People do not usually donate dirty clothes.

Today Boer receives more garments than he can process, almost all from Germany, which includes 75% of the discarded fashion.Not enough trained employees.In the t -shirt classification position I noticed a man of a certain age."It's my father," he clarified.He is retired, but keeps leaking a hand.

What worries the Boer the most is how fashion is changing.Right now the company resells 60% of what it collects.The garments that remain in use and get back are better for both for Boer and the planet, because they avoid replacing the material and energy invested in their preparation."They are the ones that finance the business," he said.The other 40%, the clothes that nobody wants, is recycled to make rags or is crushed to make insulators or mattress stuffed.A part is incinerated.The recycled fraction includes more and more cheap clothing garments, shattered.Boer loses money in almost all cases.Fast fashion, he confessed, could lead his business to ruin.

There is a form of recycling that reports a modest benefit.Boer has been sending wool and other knitted jackets and other garments to Prato, in Italy, which, with mechanical media, recover long fibers that then transform into new garments in tarm.Polyester and woven cotton cannot be recycled so, since the fibers obtained are too short.There are half a dozen start-ups working on chemical recycling technologies of these fibers.To foster its development, Boer believes that the European Union should demand that new clothing contain, for example, 20% recycled fibers."In 10 years we will see it in progress," he said..It is unavoidable".

In the Ellen MacArthur they spoke to me with enthusiasm of a different business model that encourages circularity in multiple economic sectors and is based on renting instead of buying.Internet clothing rental companies today are less than 0.001% of the world fashion market, but they grow quickly.

In theory, rent is more sustainable: if many people share the same garment, we will fix ourselves with less clothes.In practice it is not so clear;It is possible that customers limit themselves to adding luxury rentals to their cabinets, and renting will also increase the packaging, sending and dry cleaning of garments.In an article published in Elle, the journalist Elizabeth Cline, author of two books on fast fashion, tried to elucidate the advantages and inconveniences."Putting on what you already have in the closet is the most sustainable way to dress," he concluded.

Food

The population cannot adopt circularity on their own;You have to change the system itself.But every individual choice we make has its importance."The key is, to start, use less things," says Liz Goodwin from the World Resources Institute.

In 2008, the Residue and Resources Action Program (WRAP, for its acronym in English), then directed by Goodwin, made one of the first great studies on food waste.This non -profit organization studied more than 2.100 British families who had accessed an inspectors team to review their garbage and weigh to the last rest of food."We stayed on stone," says Goodwin. ".We find entire chickens in your container ».Almost half of the salads and a quarter of the fruits ended up in the garbage cube, as well as about 360.000 tons of potatoes a year.In total, the British were discarding one in three grocery bags.

And it turned out that they were no exception.On the planet it is wasted around a third of all the food, with an annual cost that is around the billion dollars, Richard Swannell, global director of Wrap explained to me.Before that study, no one suspected the amount of food - and money - that was wasted in Britain.

Wrap launched an informal tone advertising campaign ("Love food, hates waste").He collaborated with female groups by disseminating tips not to throw ingredients.He also managed to make food chains adopt a series of simple measures: clearer and longer expiration dates;smaller containers that can be closed again;leave 2x1 offers in perishable products.They were a lifetime practices that had been lost, but they worked.In 2012 the volume of food waste in Britain had fallen 20%.

That advance has been losing bellows in recent times;Anyway, no one has said that the waste of food will be solved only with common sense.Maybe it is necessary to apply artificial intelligence.From a remodeled factory of the London district of Shoreditch, Marc Zornes, Winnow Executive Director, disseminates the benefits of a high-tech solution that its start-up has already installed in 1.300 Professional Kitchens: The Smart Garbage Cube.

Zornes made me a demonstration in his meeting room with a plastic chicken thigh.Every time a chef or waiter throws a pot or a plate of food at a winnow bucket, a scale detects the added weight and a camera takes a photo.The AI software identifies the newcomer residue and shows its price on the screen.

Zornes states that its clientele reduces its waste of food systematically when listening to its garbage cubes.Bufé breakfasts are a paradigmatic case, he said;Almost everything that is left over is discarded."When you start quantifying the problem, you start solving it," he told me.Discarding something means losing benefits.I had crossed Winnow's graphite portal with the idea of finding a lot of noise and few nuts;I thought I had to talk about Winnow to my nephew, chef at the Ritz-Carlton.

Days later I lived a similar experience in Amsterdam when I visited Insock, a restaurant that prepares high gastronomy from food surpluses.In a sober room but cozy lighting, I sat under a wooden poster that carried the account of the "rescued food": 780.054 kilos.One of the founders, Freke Van Nimwegen, told me his story while I was realizing my closed menu.

Van Nimwegen had finished the business science career two years ago and worked in Albert Heijn, the largest Dutch feeding chain, when he discovered the problem of food waste.In his role as a store sub -shot, he set out to do something about it, but he ran into a wall: food banks would accept part of the bread, but not all perishable products.In 2014 he devised the concept of INSOCK along with two colleagues and convinced the company to be involved.From an ephemeral place they have managed the restaurant in which we talked and two others, in Utrecht and The Hague.

"It's not that we dreamed of founding a restaurant chain," he said, ".What we wanted was to do something with the waste of food ».

They brought me the main dish: fried goose to the kentucky."Watch: there may be pellets in the flesh," the waitress warned me.Schiphol airport, explained Van Nimwegen, has hunters hired to shoot wild geese that could spoil the aircraft engines.Before they incinerated the folded birds;Now they take them to the restaurant.The fried goose was somewhat corrected, but tasty and without pellets.With a eggplant chutney and a red pepper coulis, it entered great.

Insock chefs improvise with what comes to them.The ingredients come from the Albert Heijn chain, but also from direct producers, including farmers."It's very easy to blame the supermarket," said Van Nimwegen. ".But the full supply chain, including the client, wants everything in stock.If you think about it, we are very spoiled.Companies do not want to sell us a "no", so they always have a bit too much of everything ».

In 2018 Insock began to supply surplus food to other restaurants.Today Van Nimwegen's priority is to sign supply contracts with company dining rooms."The most important thing for us is to add volume," he said, ".In these centers they eat thousands of employees ».Dutch have reduced food waste by 29% since 2010, according to a government report, even more than the British.

For desserted, cooked red fruits in red wine taken advantage of the bottles that had been open for some time in the bar.The account was accompanied by two deformed fruits.I kept them to complete the meals that I intended to rescue the buffet.

Opportunities

Leaving the trap in which we have fallen with the linear economy and returning to an economy in the image and likeness of nature will demand large amounts of "divergent thinking", for using the psychological term.In Copenhagen I stopped to admire the new municipal incinerator, which burns garbage to obtain energy and certainly departs from the standard: the cover has a skiing track that works all year.But in reality I was heading to the neighbor Puerto de Kalundborg, a kind of circular economy icon.

When I arrived, I sat in a meeting room that housed the directors of 11 industrial plants, all belonging to different companies, which have forged an unusual bond: they use the waste of the others.The president of the collective, Michael Hallgren, directs a Novo Nordisk plant that manufactures half of the planet's insulin and that, together with his co -defilial, Novozymes, discard 300.000 tons of yeast.That waste is taken into a tank to a bioenergy plant in which microbes make it enough biogas to serve 6.000 homes and fertilizer to pay about 20.000 hectares.It is just the last of the 22 waste barter - water, energy or materials - that make up the Kalundborg symbiosis.

It emerged by chance, said Lisbeth Randers, municipal coordinator of industrial symbiosis;He was curdling over four decades based on successive bilateral agreements.A prefabricated partition company was installed in part because the residual gas provided by the oil refinery was available as a source of energy at a good price;Later he got plaster from the neighboring carbon power plant, which produces it by capturing the smoke dioxide of the smoke that emits.None of the above was launched for environmental reasons, but at the moment of truth, said Randers, Kalundborg's symbiosis cuts carbon dioxide emissions in 635.000 tons per year, while saving participants almost 25 million euros.

In the fields of Westfalia, German land of a famous ham and - not by chance - of a large population of pigs, I met a woman who, without having engineering studies, has designed an industrial -scale solution for one of the most problemsGraves of the region: excess slurry.Nitrates filtered from overfertilized crops have contaminated groundwater in 25% of the German territory.A typical farmer of the periphery of Velen, where I met Doris Nienhaus, can spend 36.000 euros a year to carry in trucks almost 2.000 cubic meters of slurry to more than 150 kilometers away to deposit them in fields still without oversupply.Sooner or later that will be economically unfeasible, "said Nienhaus.

Its solution is to create a basic nutrient extraction plant - phosphorus, nitrogen and potassium - of the purine.Nienhaus, who worked at the Regional Agricultural Federation and has raised pigs, convinced 90 farmers to invest 7.6 million euros.The slurry of its farms is digested by microbes and the resulting biogas feeds a generator that supplies electricity to the plant;The surplus is sold to the network.High speed centrifugers, a polymer of own design and a series of ovens separate the digestor porridge in a dark liquid, rich in nitrogen and potassium, and an ash that is composed of phosphorus by 35%.All this will be sold;The plant will not generate waste, Nienhaus told me.When I visited her, I was in the test phase.Nienhaus showed me his first phosphorus niche in a white saucer, as if he had discovered gold pepitas.

There was a time when all farmers and ranchers worked with circular economy: they only had the cattle they could maintain with their land and the animals did not excrete more than what that soil could absorb.Industrial livestock broke the cycle.A few years ago I spent a time on a vaccine fattening farm in Texas;There I started thinking about the circular economy.I saw how trains of 110 cars loaded with corn produced in Iowa arrived in Hereford, Texas, and I saw the mountains of manure that were going to be transported to the agricultural farms in the area in the barley bar.And it wouldn't be better to return them to Iowa to pay corn? I asked.It is very expensive, they answered me.But if there was a central one like Nienhaus's, only the extracted nutrients would have to be transported.Maybe the circle could be rebuilt again.

When in 2006 Eben Bayer devised his invention, he studied engineering at the Rensselaer Polytechnic Institute in Troy, in New York.He was enrolled in a subject of invention, in which they taught him to use divergent thinking, and the problem he had in mind were toxic adhesives that carry agglomerate and fiberglass.Raised in a Vermont farm, had spent hours throwing wood to an oven to make arce syrup.Many times the chips stuck each other, colonized by the mycelium, the set of hyphae that make up the root of fungi.Bayer wondered if a harmless adhesive could be manufactured with that.

The first product he created with his partner, Gavin McIntyre, in the company they founded, Ecovative Design, was a packaging.They inoculated small amounts of mycelium in ground hemp fibers or wood chips, and tiny white hyphae linked the spaces between the particles, adhering them together.Discovered that they could grow this material in molds in any way.Stop growing as soon as you dehydrate it;And when you don't need it anymore, you can compose.In the last ten years Ecovative has manufactured more than 450.000 kilos of packaging for customers willing to pay a little more to be sustainable.

Lately they have taken another step: they produce articles made of fungi at one hundred percent.On the ground, the mycelium grows forming layers of filament networks, but when it comes into contact with the air, it becomes fungi.Ecovative has discovered how to deceive mycelium to adopt a hybrid growth pattern, superimposing solid microcapas."It's like a biological printer," explains Bayer.With investor financing, Ecovative is expanding a laboratory to find out how to cultivate all kinds of objects - shoe, vegan leather, edible fibers to give texture to artificial steaks - with Micelio.In 2018 the designer Stella McCartney created a bag with this material.

In the vision of the cradle to the cradle of McDonough and Braungart, the waste does not even exist as a concept.All materials are, one of two, well -designed "technological nutrients", susceptible to recycling ad infinitum, or edible or compostable bionutrients.Bayer shares that vision, but bets that the future will travel along biological roads."Bioderivated materials marry by definition with the functioning of the Earth," he says, ".The Earth ship can digest them ».

Beyond Good and Evil

That we generate garbage to sport does not mean that we are evil.It means that we are a little dumb.This is what Michael Braungart let me know when we saw each other in Hamburg.Braungart began his career as a Greenpeace activist, and in the interim he has played consulting for a long list of companies."We fight against a cultural legacy arising from religious beliefs using as a tool the concept of crib to the crib," he told me, referring to monoteoisms.The legacy that they have moved to environmentalism, he said, is the idea that nature is good and human beings, due to the effects we exert on it, inherently evil: at most we can limit the damage caused.Braungart believes that it is an erroneous and conformist perspective.He is an environmentalist who, like chemists and engineers, is convinced that we can improve nature.On one occasion he designed a biodegradable ice cream wrap that had incorporated wild flower seeds;Discarding it created beauty.

On the outskirts of Amsterdam I visited an office park of nine hectares designed by the McDonough study and built with materials whose selection Braungart participated.In the absence of a third of the work, the so -called Park 20/20 is already a green and pleasant office park.The facades are varied and original;the spaces, luminous and cozy;the energy, renewable;Wastewater is treated and recycled in situ.One of its most spectacular characteristics does not appear in sight: instead of the usual prefabricated concrete plates, the buildings soils are finer and more hollow, tours of steel beams.Thus seven plants are enabled where there were usually only six, and 30% material is saved.

In winter, the hot water of the neighboring channel, stored underground since the previous summer, runs through the ground through radiant heating tubes;In summer, the reserved cold water from the previous winter runs through the ceiling through air conditioning tubes.And, unlike the concrete plates, the prefabricated sections of soil-trench.Park 20/20 buildings are "material banks", when the construction materials are usual to constitute the bulk of what ends in landfills.

In McDonough's office, while talking about Leibniz and a world of possibilities, my thoughts arrived in an old movie entitled DIDER, which I know better than philosopher."If you don't have good dreams [...], you have nightmares," says the character played by Mickey Rourke towards the end, when his classmates and he leaves uncertain.Maybe they become successful adults, maybe not.And maybe, I thought, we are as a species in that situation: in need of a dream that marks the course to dodge the nightmare.

The circular economy is a dream in which many find inspiration to do great things.But - if I am allowed to close this trip with an etching point - there is a problem: it is also an entelechy.If we look away from the bright lights and perch it in the cold figures, the same ones that Wit showed me, it is obvious that the "circularity gap" not only does not decrease, but it increases.Our use of natural resources could double from here to 2050.Our carbon emissions continue to increase.

«Does its implementation progress at sufficient?Not, ”said Wit -.All indicators are in red numbers ».

Like the other optimistic ones I talked about, Wit believes it is a matter of time.Building a circular economy will require a cultural change of colossal proportions, of the same size as the industrial revolution."Impetu is needed," said Wit -.I think it is impossible with this generation of leaders.We will take off the next ».The generation to which he was evicting the stage was mine.But I didn't take it as personal.Yes, surely we will be raising Malvas long before the circular economy is generalized.But raising Malvas will be our contribution to the circle.

See complete infographic on the radiography of the global economy

*Luca Locatelli's photos about agriculture in the Netherlands of September 2017 are exhibited in the Guggenheim in New York.Robert Kunzig wrote about cities in April 2019.

This article belongs to March 2020 of the National Geographic magazine.